Never Lose Track Of An Ingredient Again. Track every item from supplier to finished product with full traceability that keeps you audit-ready and recall-prepared.

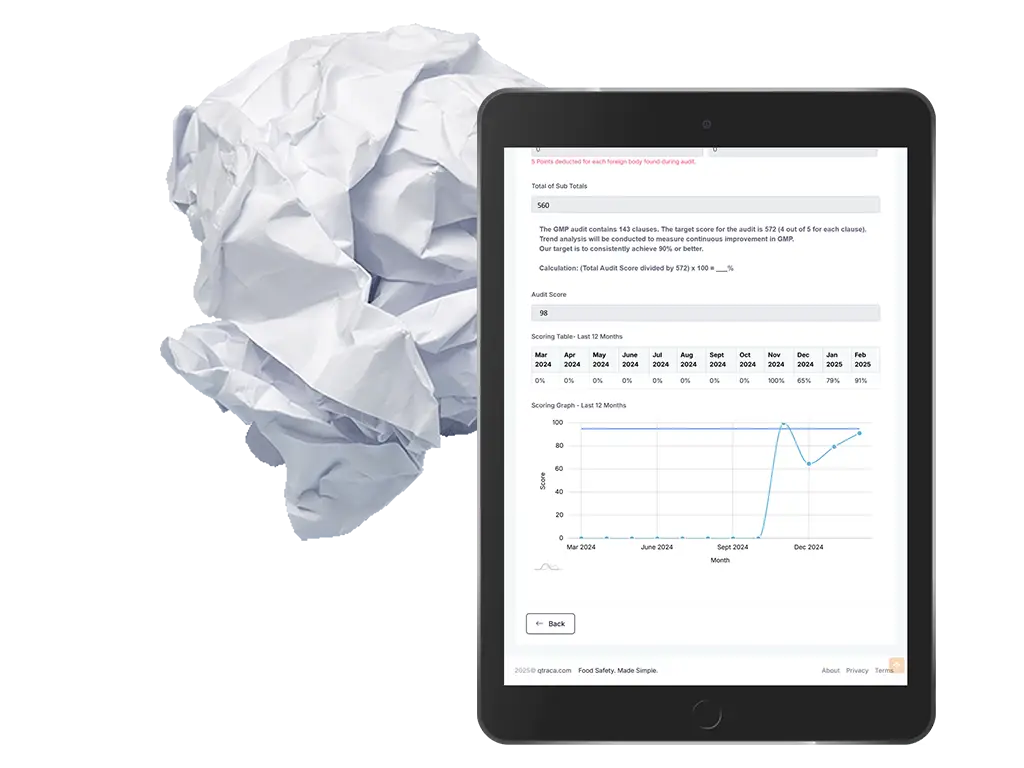

Pass Every Audit With Confidence. Create custom inspection forms, automate compliance tracking, and generate audit-ready reports instantly—catching quality issues before they become costly recalls.

Sleep Better With 24/7 Environmental Monitoring. Automatic temperature and humidity tracking eliminates manual checks, sends instant alerts when conditions drift, and creates tamper-proof compliance records.

Stop juggling spreadsheets, paper forms, and compliance headaches.

QTRACA unifies everything you need to pass audits, trace ingredients, and sleep better at night.

Sound Familiar?

Drowning in paperwork?

→ Go digital with smart forms that actually save time

Can't find critical data when auditors ask?

→ Get instant access to any record in seconds

Managing suppliers, inventory, and quality in different systems?

→ Unify everything in one platform

Spending hours on custom compliance forms?

→ Build any form you need in minutes, not days

Reacting to problems instead of preventing them?

→ Get automated alerts before small issues become recalls

Ready To Join Food Manufacturers Across Australia, New Zealand & Beyond?

See how QTRACA eliminates compliance chaos and gives you complete control.

QTRACA is a cloud-based food safety and quality management software designed specifically for food manufacturers. It combines inventory management, compliance tracking, digital forms, IoT temperature monitoring, and complete traceability in one unified platform. QTRACA helps food manufacturers streamline operations, pass audits with confidence, and maintain complete control over food safety.

QTRACA is used by food manufacturers of all sizes across Australia, New Zealand, and internationally. Our customers include a wide array of specialty food manufacturers. Whether you’re a small artisan producer or a large-scale manufacturer, QTRACA scales to meet your needs.

QTRACA offers flexible pricing based on your business size and needs. We provide transparent pricing with no hidden fees, and every plan includes limited free setup support and training. Contact us for a personalized quote, or start with our 15-day free trial to explore the full platform at no cost.

No installation required. QTRACA is a cloud-based system that works through your web browser. You can access it from any computer, tablet, or smartphone with an internet connection. We also offer a mobile app for Android for on-the-go access.

Most businesses are up and running within 1-2 weeks. Our implementation process includes data migration assistance, system configuration, staff training, and ongoing support. For simpler setups, some customers start using core features within days.

Yes. QTRACA integrates with popular accounting software including Xero, MYOB, QuickBooks, and other business systems. We also offer API access for custom integrations. Our team will work with you to ensure seamless data flow between systems.

Absolutely. QTRACA uses enterprise-grade security including SSL encryption, secure data centers, regular backups, and role-based access controls. Your data is stored in secure cloud servers with multiple redundancy measures. We comply with data protection regulations and never share your information with third parties.

QTRACA includes comprehensive support via email and phone during business hours (NZ/AU time zones). We also provide extensive online documentation, video tutorials, and personalized training sessions. Premium support plans with extended hours are available.

Yes! We offer a 15-day free trial with full access to all features. No credit card required to start. During your trial, our team is available to answer questions, provide training, and help you evaluate if QTRACA is the right fit for your business.

You own your data. If you decide to discontinue using QTRACA, you may export your data via reports to CSV. We also offer a grace period to ensure you have time to transition to another system without losing any information.

Book A Demo Now.

See how QTRACA can help you go digital and receive a 15 day no obligation trial.